3D PRINTING DESIGN GUIDE

In this design guide, we walk you through essential concepts to create 3D models suitable for 3D printing. Understanding the key limitations below will ensure your models are printed defect free. In this guide, you'll find detailed instructions on optimizing your designs for 3D printing, including, wall thickness, clearances and many more.

If your 3D file doesn’t follow all the printing guidelines, the parts may not print properly. We check the files before printing, but our system isn’t perfect. We can’t guarantee on-time delivery for parts that don’t meet the guidelines. If your file doesn’t follow the guidelines we can’t be responsible for any printing defects so please make sure to follow them carefully.

Wall Thickness

Wall thickness is limited by material characteristics: Thicknesses below 1.0mm may not print successfully and are prone to damage, Thicknesses greater than 1mm are rigid. To prevent deformation or print failure during production, extra thick (15mm+) walls may be hollowed.

MIN RESIN: 1mm

MIN FDM: 1mm

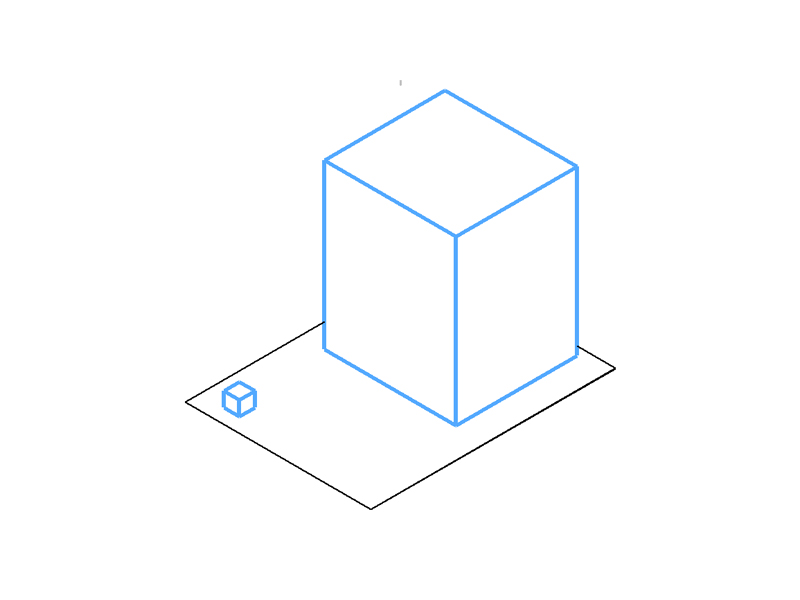

Part Size

Parts exceeding or falling below the specified sizes cannot be printed. The maximum size we can print is 350mm Length x 350mm Width x 350mm Height. The minimum size technically is a 1mm square, however this may too fragile to post process so in practise the minimum we can gaurantee is 8mm³.

MIN RESIN: 8mm³

MAX RESIN:156x278x295mm

MIN FDM: 8mm³

MAX FDM:350x350x350mm

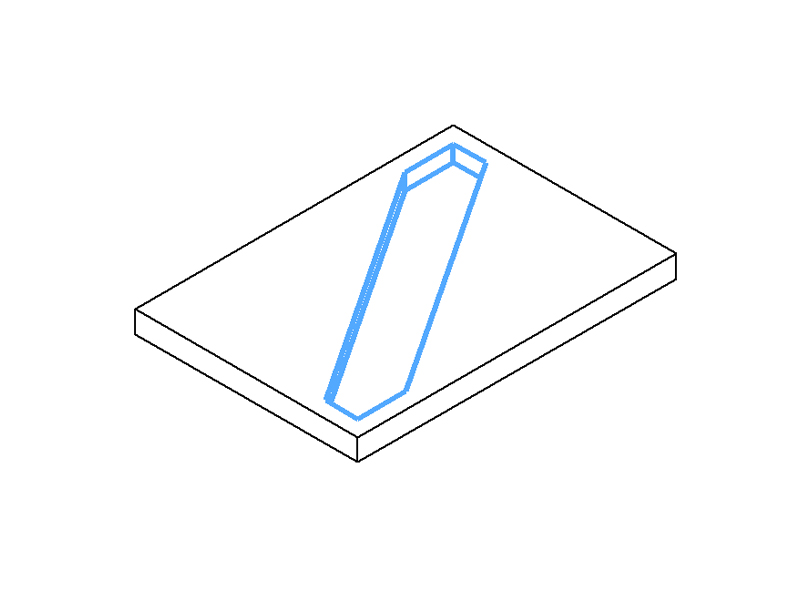

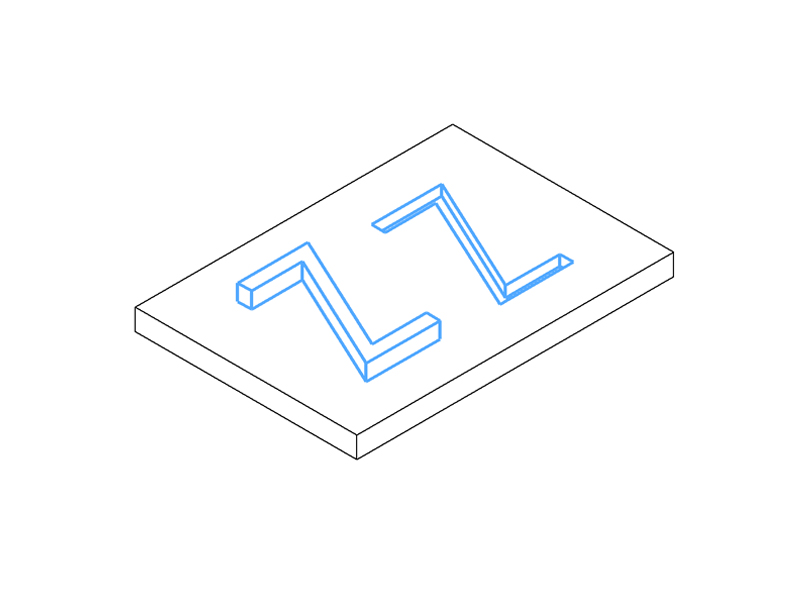

Embossed Detail

Embossed details are raised features on your model, like textures, patterns, or text. If these details are thinner than 0.4mm, they may be difficult to see or could break off during printing or post-processing. If the detail is shorter than 0.4mm it will be less visible but stronger.

MIN RESIN:0.4mm

MIN FDM 0.8mm

Engraved Detail

Engraved details are imprinted or recessed features on your model. Details must be at least 0.4mm in width and depth for any clarity.

MIN RESIN: 0.3mm

MIN FDM: 0.4mm

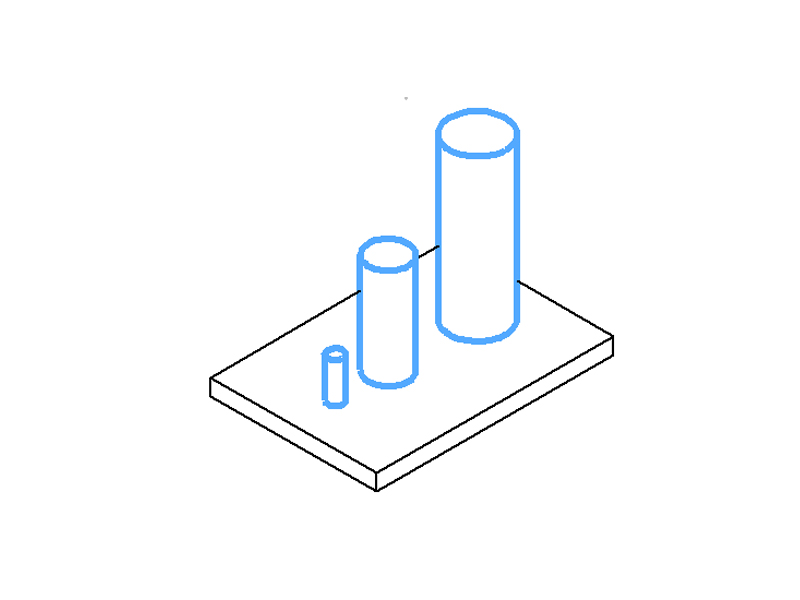

Blind Holes

To prevent uncured resin blockages a minimum diameter of 1mm is recommended, with an increase of 1mm in diameter for every 10mm depth. (e.g 30mm hole should be at least 3mm wide)

MIN RESIN: ø1mm

MIN FDM: ø1mm

DEPTH: ø+1mm/10mm

DEPTH: ø+1mm/10mm

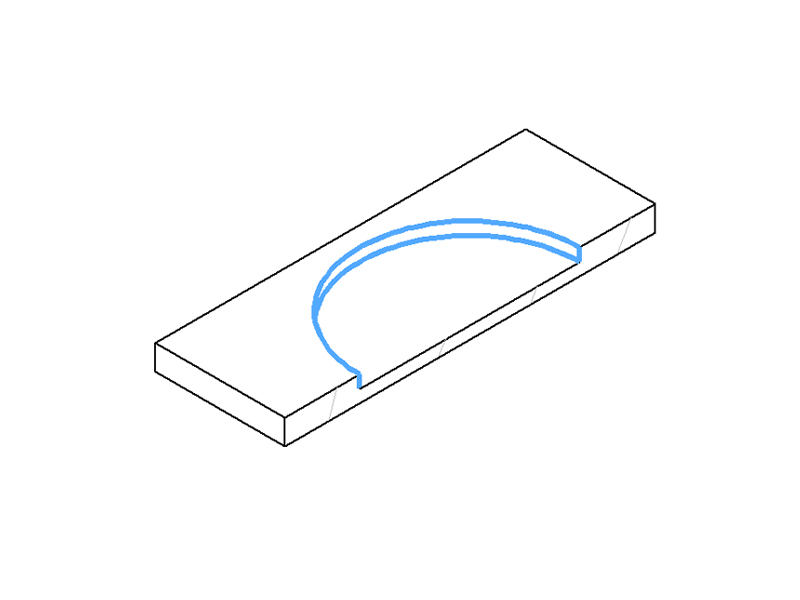

Through Holes

Through holes are slightly less susceptible to blockages than blind. A minimum diameter of 0.9mm is recommended, with an increase of 0.9mm in diameter for every 10mm depth.

MIN RESIN: ø0.9mm

MIN FDM: ø1mm

DEPTH: ø+1.mm/10mm

DEPTH: ø+1.mm/10mm

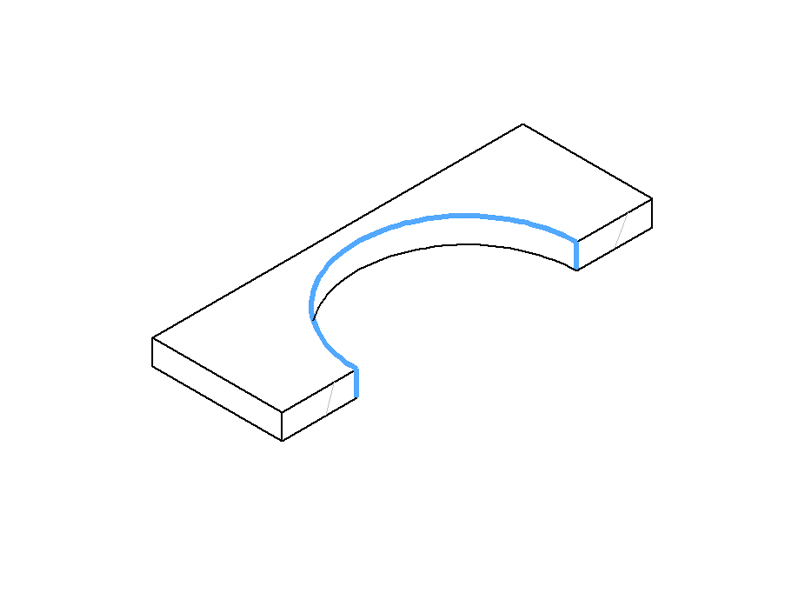

Cavities

When designing hollow parts, be sure to use large openings and avoid non-line-of-sight cavities to prevent trapping of uncured resin inside. A ideal wall thickness for hollow parts is 1-2mm.

MIN RESIN: 1mm

MIN FDM: N/A

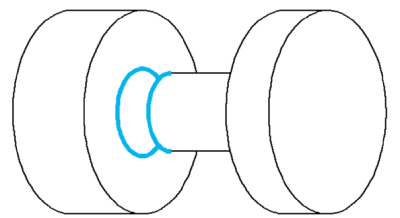

Assembly Clearance

For parts intended to be assembled post-printing. A free fit offers more space for easy assembly and movement, while a close fit is tighter and may require some force or adjustments to assemble.

FREE FIT RESIN: 0.4mm

CLOSE FIT RESIN: 0.2mm

FREE FIT FDM: 0.5mm

CLOSE FIT FDM: 0.25mm

Text Size

It’s important to consider the distance between engraved letters as well as the line weight of embossed text. Any material thickness below 0.4mm may not be visible or could break during production.

MIN RESIN: 0.2mm

MIN FDM: 0.4mm

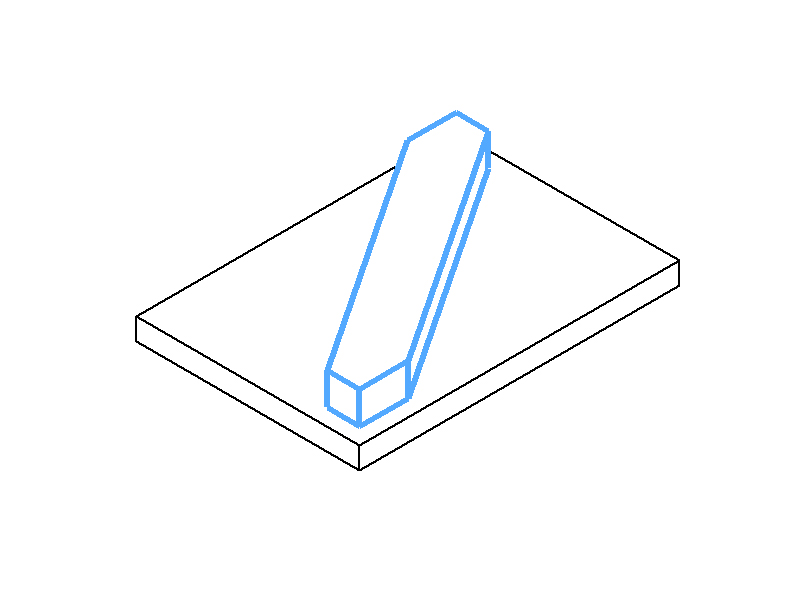

Wire Diameter

It's advisable to maintain a minimum thickness of 1mm for wires up to 20mm long, increase to 1.5mm for lengths up to 30mm, and use at least 2mm thickness for anything longer.

MIN RESIN: 1mm

MIN FDM: 1.5mm

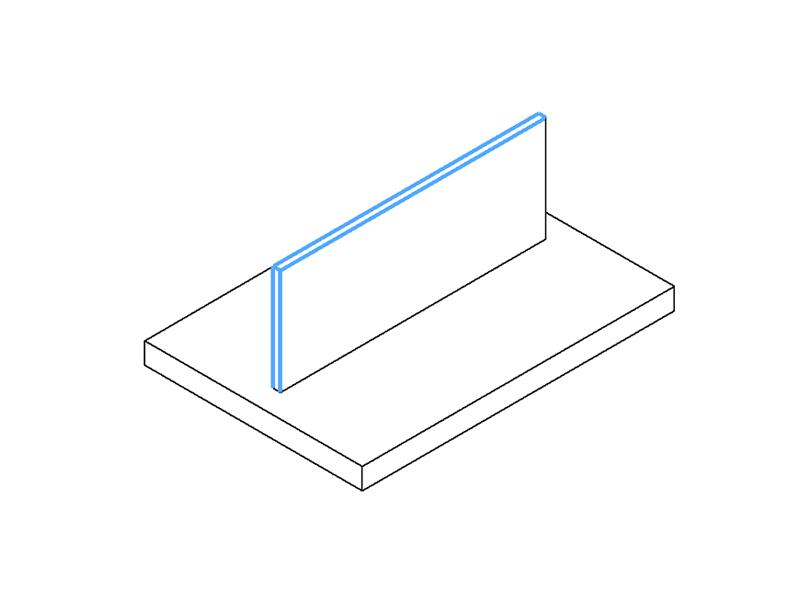

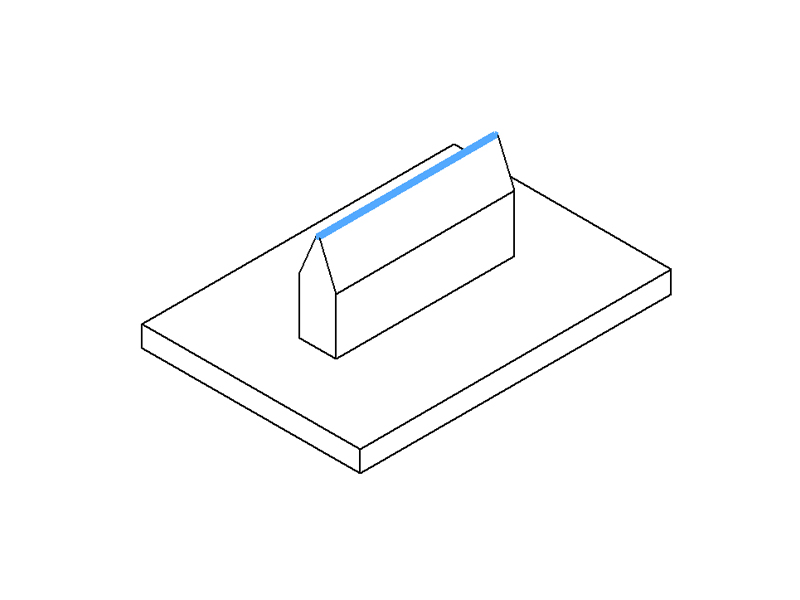

Edge Thickness

To prevent damage during manufacturing, avoid designs with edges that taper to zero thickness. Thin edges are prone to damage; it's recommended to blunt these tapered edges to a minimum thickness of 0.3mm.

MIN RESIN: 0.3mm

MIN FDM: 0.5mm

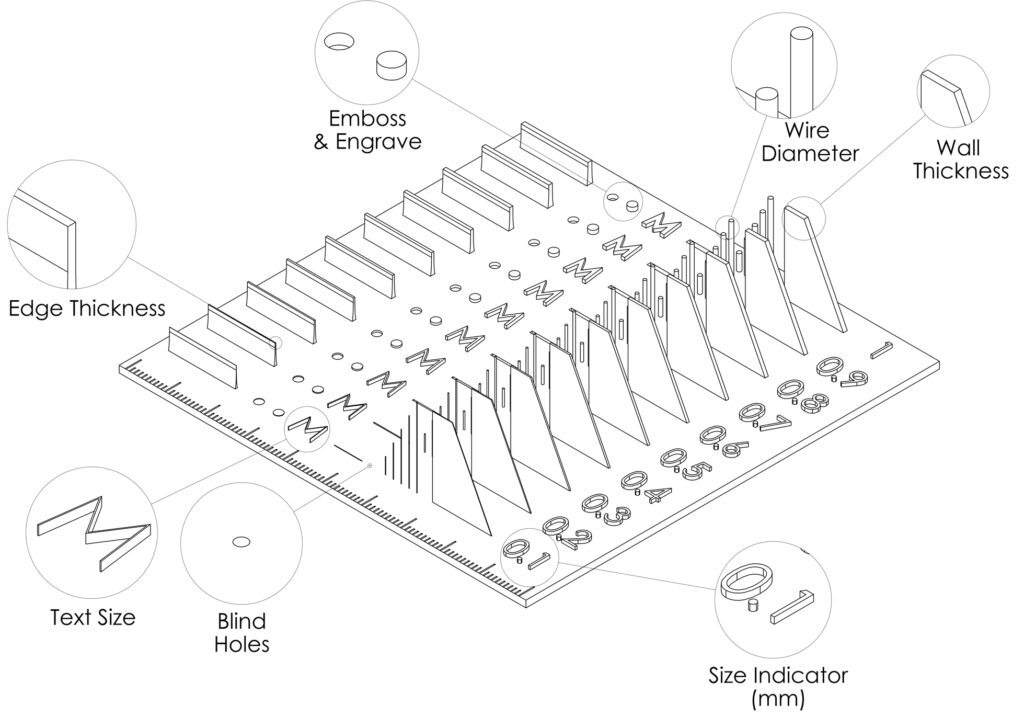

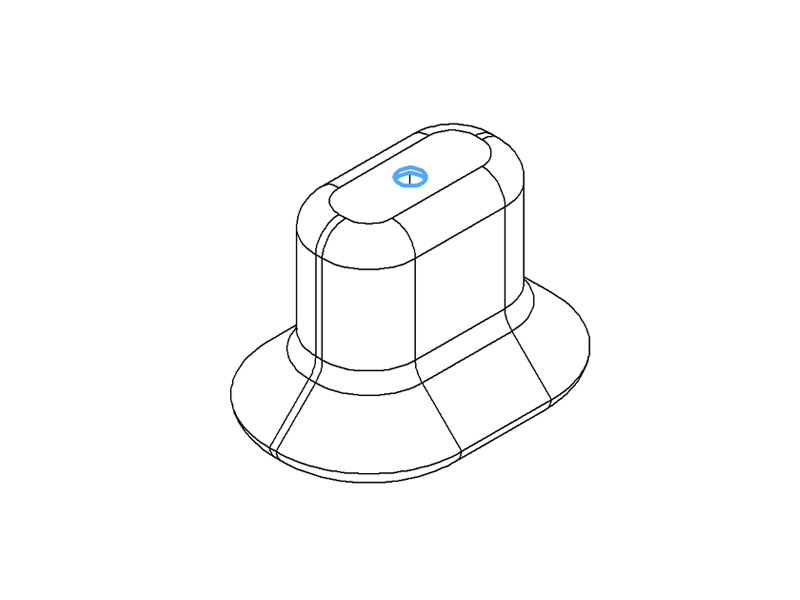

Design Limitations Model

Generally, we guarantee wall thickness, holes, extrusions, engravings, text sizes, edge thicknesses and wire diameters over 1mm. We understand that some features in your design may need to be under this minimum threshold. We will print models under the thresholds, but it is at your own risk. We have created a design limitations model below.

As you can see our resin 3d printing can produce details finer than the 1mm minimums we guarantee. In fact, our resin can produce details as fine as 0.2mm with ideal geometry and print conditions. Please refer to this model to better understand these limitations under 1mm thick.