UK based

3D Printing Service

Specialists in SLA & FDM 3D Printing technologies

How To Order

7 Essential File Preparations

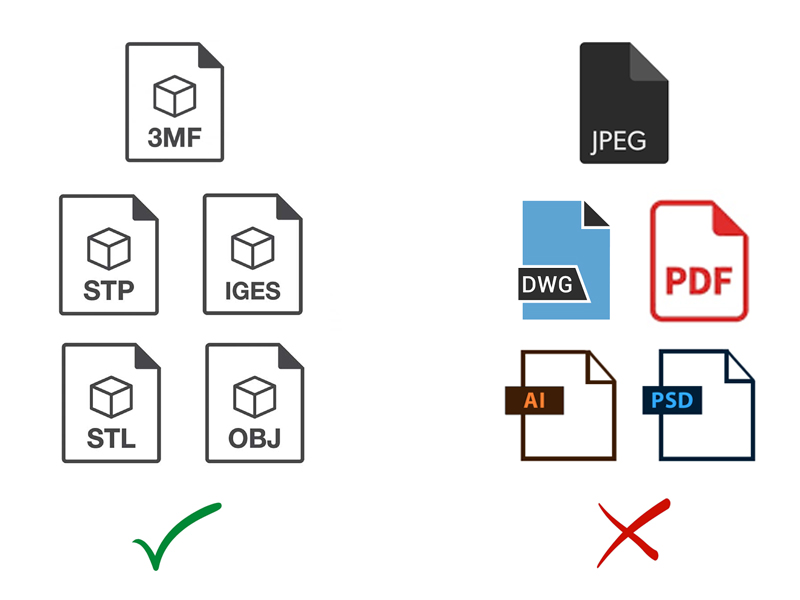

File Formats & Data size

Max file size of 200 MB per file. Our system accepts STL, OBJ, STP & 3MF. Files larger than 200mb? Don’t worry! Create a low-resolution version, the cost is the same whether it’s low or high resolution. After ordering please email your high-resolution file to info@microworkshops.co.uk

Non-Manifold Geometry

Non-manifold geometry is the most serious file problem. In some cases, it’s minor, and in others, it renders the file completely unprintable. Non-manifold geometries are those that have shared edges, inverted normals, overlapping faces, shared vertices, missing, and zero-thickness surfaces. Unfortunately, we cannot guarantee that a non-manifold model will print defect-free, if at all.

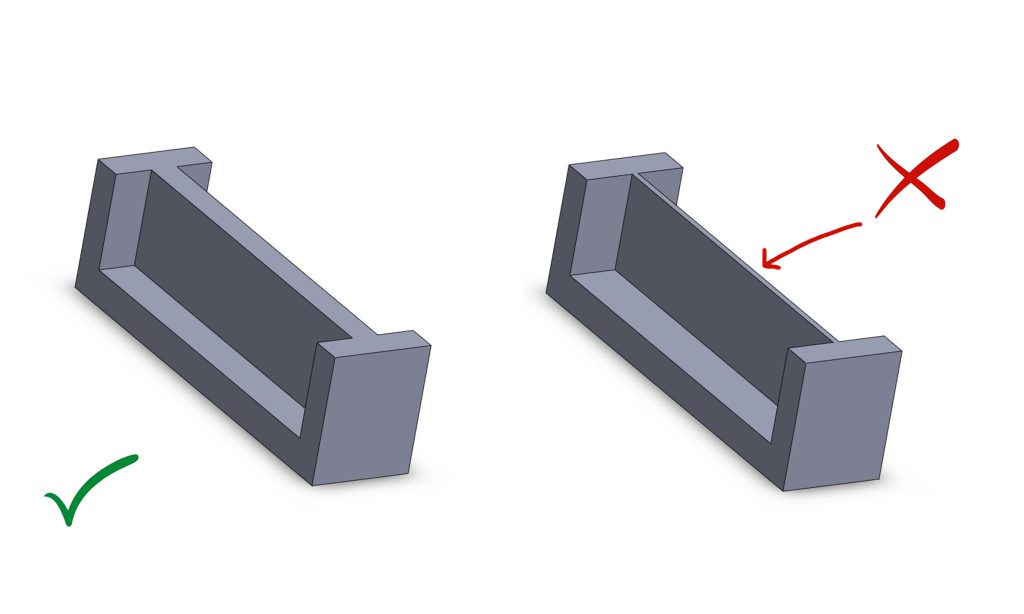

Wall Thickness

We only guarantee parts above 1mm in thickness. We can print thinner things, but it’s at your own risk. Thin areas of your model that fall below our minimum thickness may not print. The best-case scenario is that the thin areas do print. In some cases, the entire model prints fine except for the thin areas, and in the worst cases, the thin areas fail to print, causing the entire model to fail. We do our best to check every single model for printing; however, sometimes thinner parts may be missed. To ensure your print succeeds, thicken all walls above 1mm.

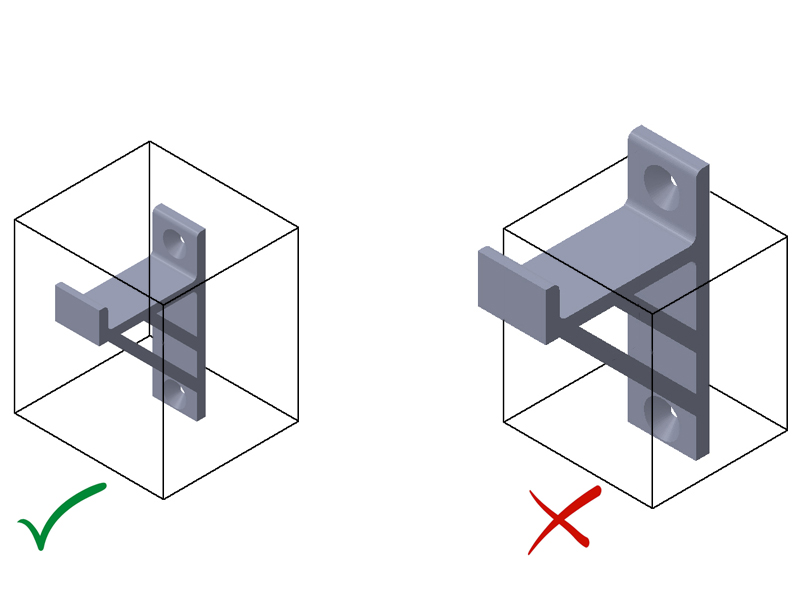

Scale

First check your scale/size. If you model is larger than the printers build volume it must be scaled down to fit. The max print size for SLA resin is 156 x 278 x 295mm & FDM max size is 350 x 350 x 350mm

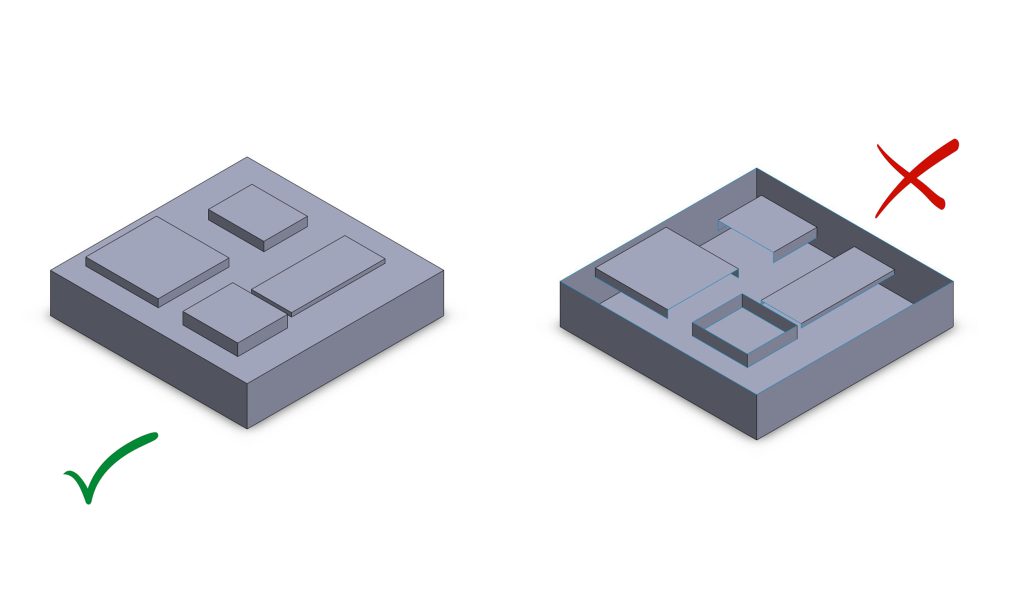

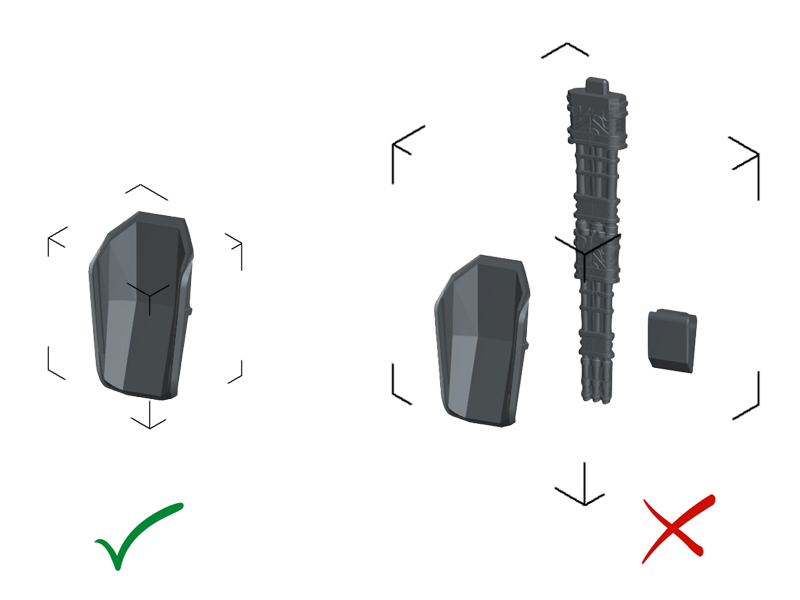

Single Body Files

When uploading files with multiple bodies contained inside, it often prompts the quoting system to fail. In cases where it does give a price, it bypasses our per part pricing parameters which invalidates the cost. Therefore, all files must contain just one body/part.

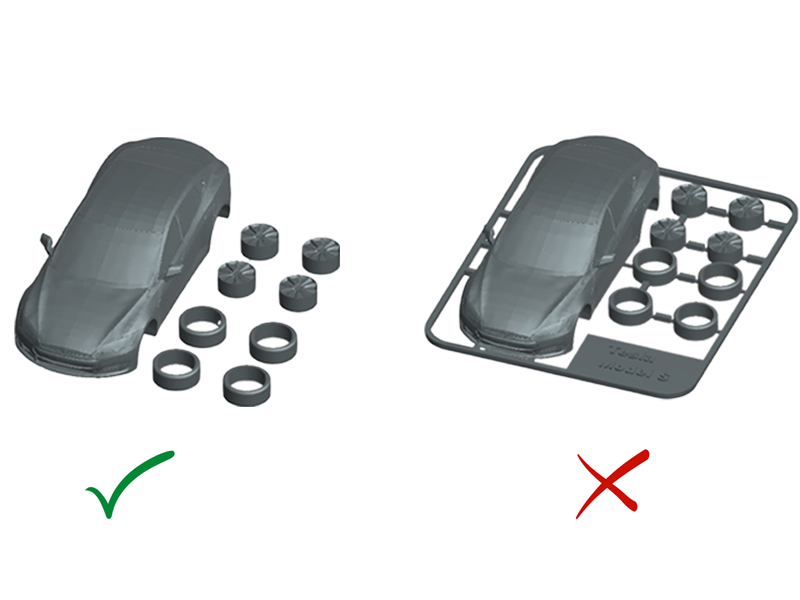

Spruing

Spruing complicates FDM and SLA 3D printing greatly. Batching parts together this way means we cannot orient parts independently of one another so some parts would be well oriented and others won’t. Spues obstruct the path for essential printing supports and it bypasses our per part pricing parameters which invalidates the cost. All sprued files and airfix kits are not accepted.

File Resolution

Overly low-resolution files will have a faceted surface as shown by the trophy on the right. The max resolution our system can upload is 200mb per file. Ensure your files are high enough resolution by viewing your files before printing. The trophy on the left is a more than adequate as you can see by its smooth round appearance.