PLA Plastic

Cost effective biomaterial, excellent mechanical properties & fully recyclable

High Quality PLA Plastic Prints

Delivered to Your Door in Just 2 Days

PLA Plastic

Overview

PLA is a strong, stiff biodegradable plastic. Its processed using a FDM printer, meaning it enters the printer in filament form, its heated to melting point and extruded out the print head as it prints into its final shape. It has properties that we have found are suited well for a range of difficult geometries including forms prone to warping.

It has a remarkably low shrink rate of 0.1-0.2% which is how we produce forms within tolerance and free of warping.

The filament diameter is highly accurate (+-0.03mm) so parts are free of inconsistencies. All our PLA is kept dry boxes always, this ensures the plastic absorbs no moisture which would decrease print quality in ways you can and can’t see with our eyes.

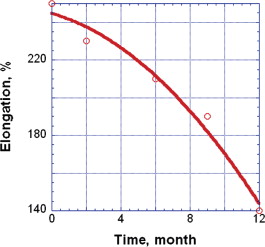

Its elongation at break is 20% which prevents it from becoming brittle, provides a little flexibility and improves impact resistance.

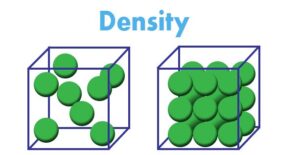

Our default print settings apply a wall thickness of 1.2mm and a hexagonal infill pattern of 20% density. Our maximum infill density is 50%, anything more than that clogs the machinery and adds almost no extra strength.

Typically, its best suited for prototyping purposes, its cheap so it’s more affordable when many iterations are required. Its lower detail than SLA resin and the build lines are visible, but its accurate and more than detailed enough for a huge variety of applications.

- Printing Technology : FDM

- MAX PRINT SIZE : 350mm(Y) x 350mm(X) x 350mm(Z)

- MATERIAL : PLA Plastic (polyactic acid)

- COLORS : Black, White & Grey

- LAYER HEIGHT : 0.1 - 0.2mm layer height

- PRODUCTION LEAD TIME : 1 or 3 working days (work days monday-friday)

- MINIMUM ORDER : £25

Properties

Cost Effective

PLA plastic the most used filament in FDM printing as its cheap and has a great balance of mechanical properties that suit many uses. PLA is a great choice when you need large batches given its low unit cost.

Strong & Stiff

Its strong and impact resistant like ABS. Its lots more rigid than ABS and more environmentally friendly. Parts thicker than 10mm can withstand large forces without any permanent bending.

Accurate

PLA has an extremely low shrink rate (0.1-0.2%) which makes its great for functional parts that require high dimensional accuracy. Generally speaking if the part is less that 100mm long then it will be within 0.1mm of its target size.

Environmentally friendly

PLA plastic is derived from corn starch which categorizes it as a biomaterial. It’s not just recyclable, its compostable too. It can last some time in standard compost but commercial composts with elevated temperatures fully break it down in as little as 30 days.

Tolerance/Accuracy

The vast majority of our prints are within +-0.2mm (or +-0.2%). We offer a guaranteed tolerance of +-0.4mm (or 0.4%), however 95% of our parts are significantly more precise than the minimum tolerance we offer.

If the part is less that 100mm long, then it will be within 0.1mm of its target size.

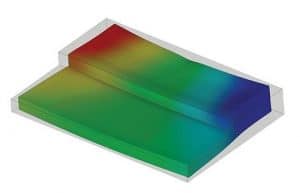

In rare cases some geometries are prone to warping which can lead to results outside of the guaranteed tolerance, if this is the case, we can usually reorientate the print direction to compensate.

| Mechanical Properties | Test Method | Value |

|---|---|---|

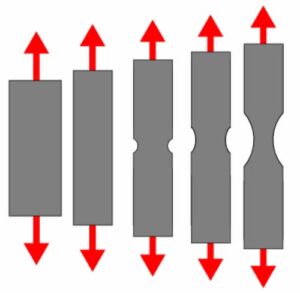

| Ultimate Tensile Strength

| GB/T 1040 | 63 MPa |

| Elongation at Break

| GB/T 1040 | 20% |

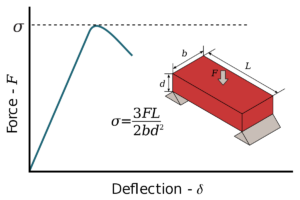

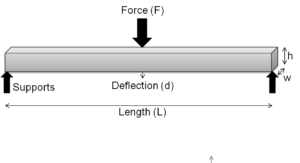

| Flexural Strength

| GB/T 9341 | 74 MPa |

| Flexural Modulus

| GB/T 9341

| 1973 MPa |

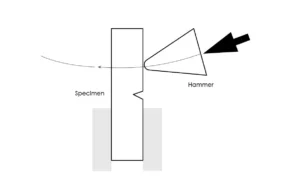

| Notched IZOD

| GB/T 1843 | 9 KJ/m2 |

| Shrinkage

| / | 0.1-0.2% |

| Density

| GB/T 1033 | 1.23 g/cm3 |

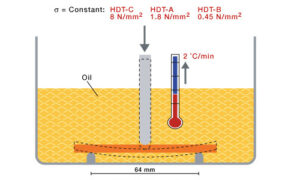

| Heat distortion temperature

| GB/T 1634 | 53 degrees C |

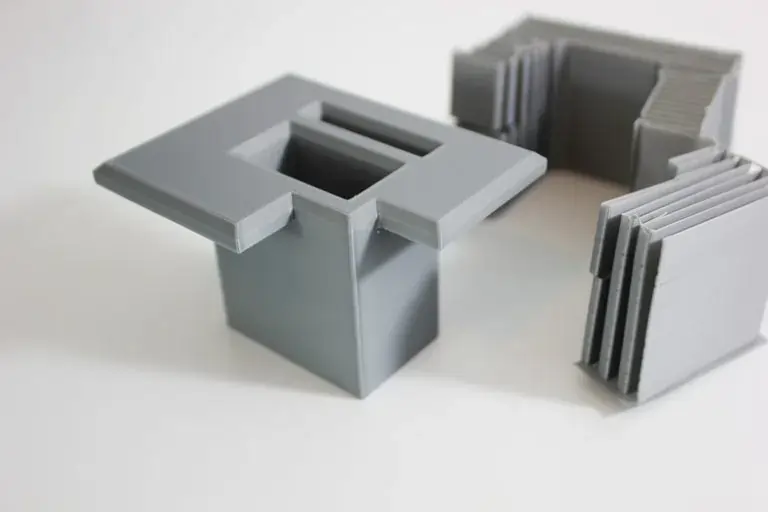

Look/Feel/Finish

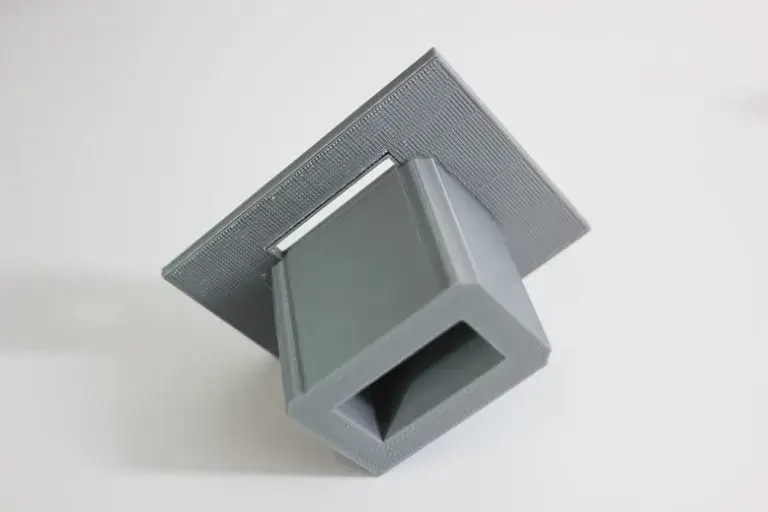

Below you will see pictures of the PLA prints fresh out of the printer. Unlike resin PLA comes as it comes and not much can be done in the way of surface finishes. By default, we remove all printing supports. The surface is a little glossy. Build lines are visible up close when printing with a 0.2mm layer height setting.

1 - (Above) shot from arms distance (bearing included for scale reference)

2 - (Above) build lines become visible when looking closeup

3 - (Above) shows the cross section which reveals the infill structure (at 20% infill our default density)

4 - (Above) shows a our fine layer height setting on the left (0.1mm layer height) and a standard on the right (0.2mm)

5 - (Above) shows the 3 colors we provide

6 - (Above) shows a print which requires support structures

7 - (Above) shows the support structures removed